Descriptions

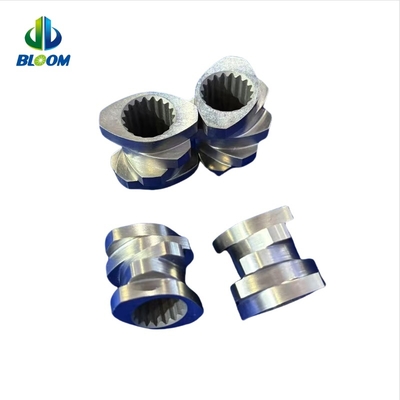

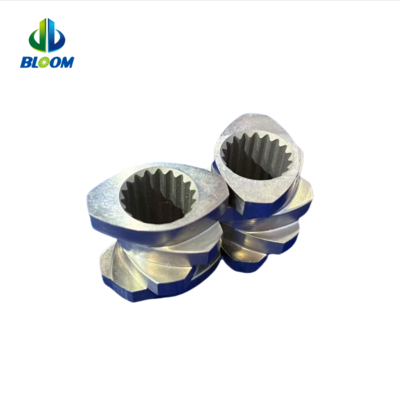

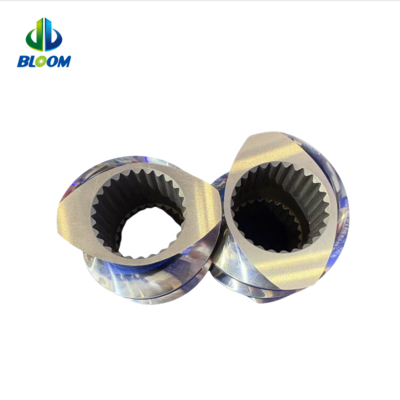

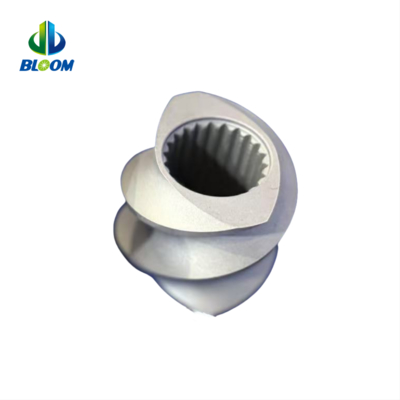

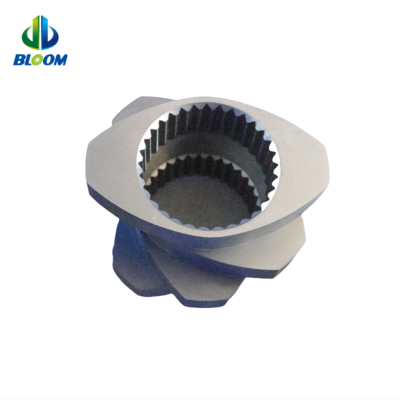

Each threaded element installed on the mandrel plays a different role and functions in the

production process. The threaded element adopts a modular structure, allowing for adjustments

and variations in the screw combination to meet the process requirements of different products.

The advantage of this structure is that when it is necessary to replace the threaded elements, it

can be done quickly, improving production efficiency. We will, based on the actual working conditions,

use the most suitable materials to make accessories, reduce maintenance and extend service life.

Types based on different functions

| Item |

Functions |

| Convey Screw |

Convey materials. This is the most fundamental and commonly used type of component. |

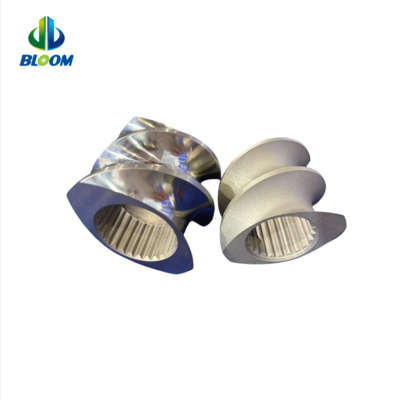

| Mixing Screw |

The core component of mixing (distributed mixing and dispersed mixing). The materials are cut, folded, stretched and reoriented through the staggered arrangement of paddles |

| Kneading Block & Disk |

Misalignment Angle: This is the most crucial parameter for controlling the mixing characteristics of the kneading block |

Production process

From raw material to finished products

Reference cases

Company Profile

Bloom(Suzhou) Materials Co., Ltd is mainly focused on offering the most suitable screw and

barrel replacement for old original extruder accessories to extend their productive life, to meet

critical requirements of several industries among different customers.

Bloom Suzhou Materials can offer screw elements for all compounding needs in processing

zones such as intake, mixing, melting, venting, and metering. We provide tailored solutions

and optimized alloy material to satisfy high wear, high corrosion, and other specific application

needs, getting optimal lifespan. The use of advanced manufacturing and quality engineering

guarantees the best-performing products.

With experience in supplying replacement screw elements for Leistritz, BUSS and Corperion

Extruder extruder worldwide, Bloom is a trusted partner across the globe.

Applications

FAQ

1.How do Iknow if my screw or barrelneeds replacement?

signs of wearinclude decreased performance,increased energy consumption,and noticeable

damage to the screw flights or barrel surface.

2.What are the common causes of wear in extruder screws and barrel?

common causes of wearinclude abrasive materials,high temperatures,and prolonged usage

without proper maintenance.

3.How to optimize the performance of my injection screws?

optimizing performance involves regular monitoring ofwear,adjusting materials, and considering

upgrades or enhancements such as coatings or design modifications.

4.What measures can be taken to minimize wear in feed screws for plastic extrusion?

Minimizing wearinvolves selecting appropriate materials,improve design, maintaining proper

alignment,and implementing preventve maintenance schedules

5.How does wear in conical screws impact the efficiency of mixing and compounding processes?

Wearin conical screws can result in uneven mixing,reduced throughput,and increased energy

consumption,affectng the efciency ofmixing and compounding processes.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!