At Bloom(Suzhou) Materials Co. Ltd., we start with the highest quality raw materials, meticulously selected to meet our stringent standards. We conduct comprehensive testing throughout the production process to ensure that our nickel-chromium and tungsten molybdenum components consistently exceed industry benchmarks for wear and corrosion resistance. This dedication to quality ensures that our customers receive durable and reliable parts, minimizing their maintenance costs and extending the lifespan of their equipment.

Our Test Machines for Raw Materials

Production and Raw Materials Control

What sets us apart from most accessories suppliers in the market is that we can start with raw materials. The raw Materials for nickel based alloy powder and HIP powder metallurgy materials are self-made.

Raw Materials quality Control:

Serious Process Control

Semi-finished Products Testing:

All Products are marked with codes and processing dates in the production process flow, which not only enables the execution of the production process flow, which not only enables the execution of the production process from beginning to end , but also enables accountablility to the process and individuals, facilitating timely detection and resolution of problems.

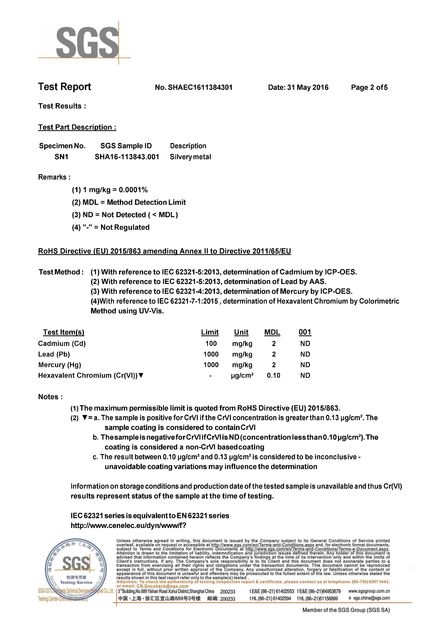

Strict Finished Products Testing

All Extruder Parts Finished Products are tested using a Coordinate measuing instrument imported from Germany. and then carefully compared and vertified by the staff. Other tests such as hardness Testing and surface dye penetrant testing are also used to fully ensure the precision and perfect quality requirements of the products.

Main Product Testing Equipments we have

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!