Insulation KCF Guide Pins & Projection Welding Guide Pins For Automobile Industry

1 . Descriptions:

Bloom welding is the manufacturer of the KCF bars,and we also make the KCF guide pins.We offer different sizes guide pin,locating pin,bushing,sleeve.Our material include KCF alloy material,ceramic coated,Zirconia ceramic,Silicon nitride ceramic etc.We not only can make the standard size and also can make the KCF pins according to your drawings.Welcome your inquiry.

We produce and supply all kinds of resistance welding accessories,welding electrode,electrode tips,cap tips,electrode holder,electrode arm,adapter,welding wheel,straight shank,bent shank,KCF guide pins,KCF sleeve,tip dresser tool,welding tester.

2. Properties

|

Code

|

Composition(wt%)

|

Tensile strength(N/mm2)

|

Yield strength(N/mm2)

|

Elongation(%)

|

Features

|

Application

|

|

KCF

|

Cr20,Al3,Fe Bal

|

539

|

392

|

15

|

Oxidation resistant

|

Brazing jigs,Guide pins for projection welding

|

We offer various sizes of KCF guide pin and KCF sleeves. The standard kcf pins are always in stock.Also supply customized pins according to your drawing.With excellent insulation performance and long-life,our kcf guide pins are directly or indirectly used on GM,VW,TOYOTA etc.automotive welding factory.

KCF Guide Pin Technical Specification

Pin Material: KCF,AL2O3,ZrO2,Si3N4,Ceramic,Stainless Steel etc.

KCF Pins Diameter:M4,M5,M6,M8,M10,M12…

Application: KCF guide pins are widely used on projection welding,nut welding,stud welding

KCF Guide Pins Advantage:

-

Good insulation performance

-

Excellent wear resistance ability

-

High temperature anti-oxidation performance

-

Good heat shock performance

What is KCF Guide Pins?

KCF material is a special metal material.Through special heat treatment process and process temperature range of 1000-1500 degree adjustment,the surface can generate a layer of 10-32μm thick high-quality insulation layer,the insulation layer and the alloy matrix has a good ability to combine.So that the material takes into account the good wear resistance and high insulation resistance.The material in the mechanical processing after formation of a variety of parts,after cleaning and heat treatment with insulation,wear and anti-oxidation of the three functions of the product.This material is mainly used in resistance welding equipment.

We generally use ceramic guide pins as a welding nut positioning pin, but because of the toughness of ceramics is poor, fragile, so now KCF guide pin instead of ceramic is more and more popular.

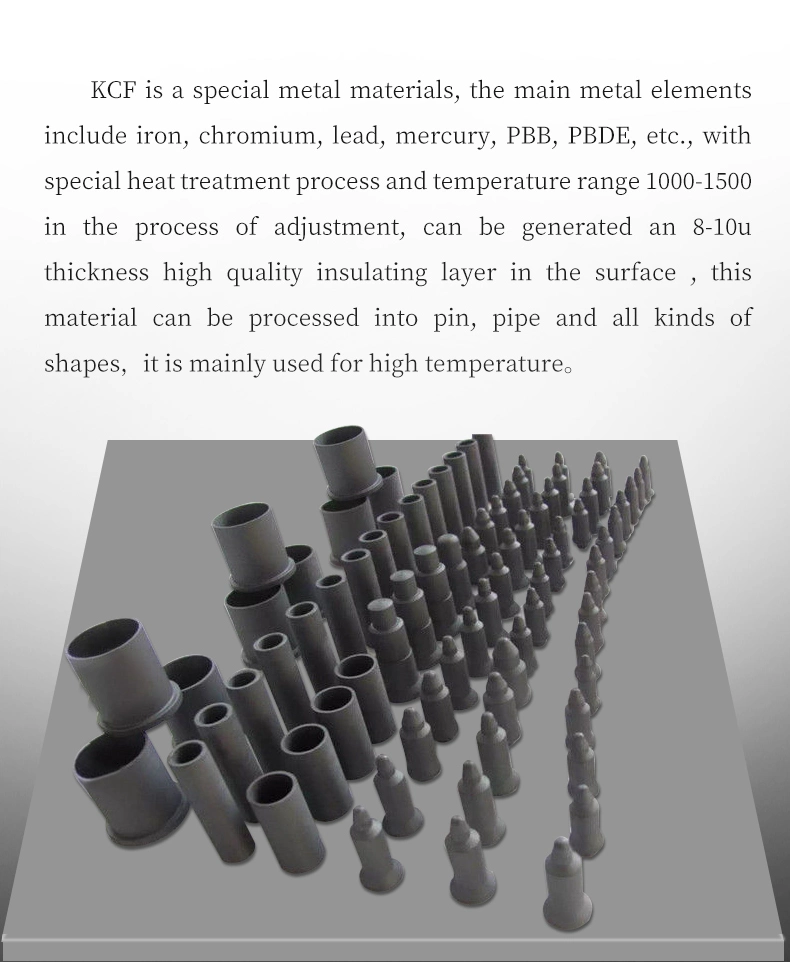

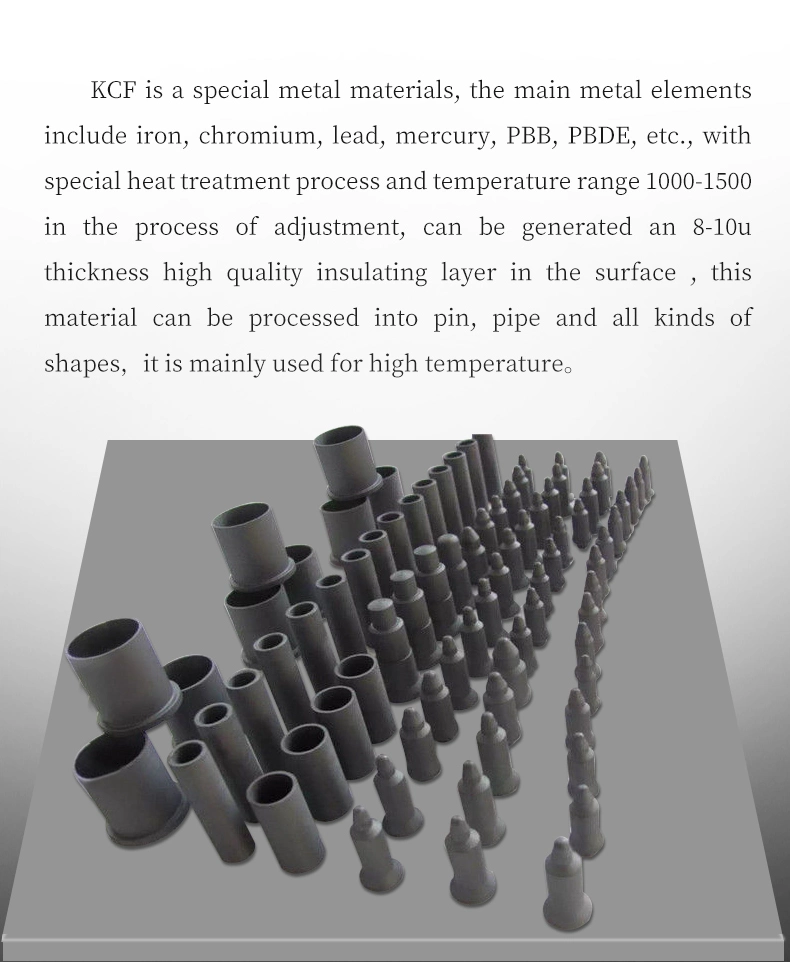

KCF is a special metal materials, its main metal elements include iron, chromium, lead, mercury, PBB, PBDE, etc., with special heat treatment process and temperature range 1000-1500 in the process of adjustment, can be generated an 8-10u thickness high quality insulating layer in the surface , this material can be processed into pin, pipe and all kinds of shapes, it is mainly used for high temperature, insulation environment protection some product parts, like bolt, nut welding in automobile industry.

KCF Guide Pins /Sleeve is not an insulation coating but a specially processed insulation material which does not peel.

Has been being used in resistance welding applications for several decades. It has an insulated skin on its surface. Any shape can be made quickly. Our standard shapes are cheaper in the business.

We generally use ceramic guide pins as a welding nut positioning pin, but because of the toughness of ceramics is poor, fragile, so now KCF guide pin instead of ceramic is more and more popular.

KCF guide pins advantages:

|

1

|

Good insulation performance

|

|

2

|

Excellent wear resistance ability

|

|

3

|

High temperature anti-oxidation performance

|

|

4

|

Good heat shock performance

|

| Ceramic (solid) |

Traditionally Silicon Nitride

-fully insulated. |

Grey, White, Beige, Blue |

High intial cost but will last longer than any other pin when conditions allow. Sosceptible to damage. Repels weld spatter. |

| KCF |

A special heal treated alloy with a hard,insulating skin |

Grey / Black |

A low cost pin with a reasonable lifespan |

2 . Sizes

W-PN Code

|

SIZE

|

Code

|

SIZE

|

|

A

|

B

|

L

|

C

|

D

|

E

|

Q

|

R

|

|

M4

|

4P

|

4.8

|

12.0

|

29.0

|

6.5

|

5.5

|

7.5

|

2

|

11.0

|

|

M5

|

5P

|

5.8

|

12.0

|

30.0

|

8.5

|

7.5

|

6.5

|

2

|

15.0

|

|

M6

|

6P

|

6.8

|

12.0

|

31.5

|

11.0

|

9.5

|

5.5

|

3

|

23.6

|

|

M8

|

8P

|

8.8

|

12.0

|

31.0

|

12.0

|

10.5

|

4.0

|

3

|

21.7

|

|

M10

|

10P

|

10.8

|

16.0

|

34.5

|

14.0

|

12.0

|

5.5

|

4

|

22.3

|

|

M12

|

12P

|

12.8

|

16.0

|

36.0

|

17.0

|

15.0

|

4.0

|

4

|

27.0

|

PN-A Code

|

SIZE

|

CORD NO.

|

Ød

|

ØD

|

Ød1

|

L

|

|

M4

|

PN-A-4.8

|

4.8

|

12

|

3.1

|

4.0

|

|

M5

|

PN-A-5.8

|

5.8

|

4.0

|

5.0

|

|

M6

|

PN-A-6.8

|

6.8

|

4.8

|

5.5

|

|

M8

|

PN-A-8.8

|

8.8

|

6.6

|

6.0

|

|

M10

|

PN-A-10.8

|

10.8

|

16

|

8.3

|

8.5

|

|

M12

|

PN-A-12.8

|

12.8

|

10.3

|

10.0

|

I-PM Code

|

NUT SIZE

|

SIZE

|

|

A

|

B

|

C

|

D

|

E

|

F

|

G

|

L

|

Q

|

R

|

|

M4

|

3.2

|

4-7

|

10

|

5

|

2.0

|

22

|

4

|

31

|

2.5

|

9.0

|

|

M5

|

4.1

|

5-8

|

10

|

6

|

2.5

|

22

|

4

|

32

|

3.0

|

13.3

|

|

M6

|

4.9

|

6-10

|

10

|

7

|

2.5

|

22

|

3

|

32

|

3.5

|

15.5

|

|

M8

|

6.6

|

8-11

|

12

|

8

|

3.0

|

23

|

3

|

34

|

5.0

|

17.5

|

|

M10

|

8.5

|

10-13

|

15

|

10

|

3.5

|

24

|

3

|

37

|

7.0

|

30.5

|

|

UNIFY

|

9.7

|

11-14

|

16

|

12

|

4.0

|

24

|

3

|

39

|

8.0

|

37.5

|

|

M12

|

10.4

|

12-15

|

16

|

12

|

4.0

|

24

|

3

|

39

|

9.0

|

41.0

|

3 . More pictures

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!