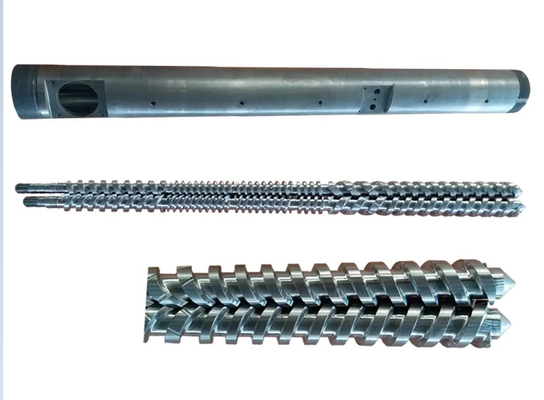

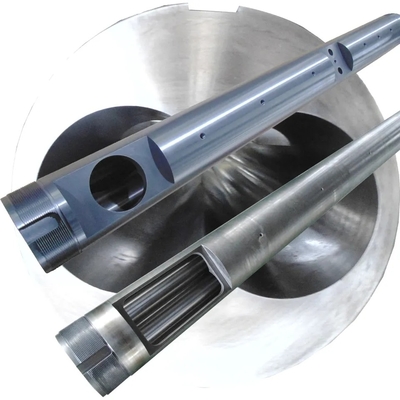

Co-Rotating / Counter-Rotating Conical Twin Screws and Barrels for Extruder

1 . Descriptions

Applications: pipe,sheet,film,wood-plastic extrusion and soft and hard PVC granulation,cable material granlation,color masterbatch granulation,engineering modified plastic granulation,PP and PE granulation,thermoplastic elastomer granulation.

Advantages:high output,low energy consumption(compared to the domestic standard"cone counter-rotating twin-screw extruder" and "parallel co-rotating twin screw extruder",the output is about two times higher and the power-power consumption-is reduced by 30-50%)

Counter-rotating Conical twin screws&barrels

Specification:ø24/ø52~ø110/ø220

Applications:PVC pipe,plate,sheet,granulation,wood-plastic extrusion.

Inlaid bimetallic layer for the inner hole of the barrel available according to customer requirements.

The compression ratio of screws can be designed according to different raw materials.

High mixing and dispersive performance: The intermeshing design of the screws and the optimized screw geometry provide excellent mixing and dispersion, ensuring homogenous and consistent output.

Excellent melt quality: The MCV series of twin screw barrels are designed to provide excellent melt quality, with low shear stress and minimal melt degradation.

High throughput performance: The MCV series of twin screw barrels are capable of processing high volumes of material, with excellent melt conveying and pumping performance.

Modular design: The modular design of the MCV series of twin screw barrels allows for easy customization and adaptation to different extrusion applications.

Plastic extrusion is a manufacturing process that involves melting and shaping plastic materials into a continuous profile or shape using an extruder machine. The plastic materials are fed into the extruder through a hopper and then melted by a heating element, which is typically a single screw or a twin screw.

There are various types of plastic materials used in plastic extrusion, including PE (polyethylene), PS (polystyrene), PC (polycarbonate), ABS (acrylonitrile butadiene styrene), PET (polyethylene terephthalate), PP (polypropylene), and PVC (polyvinyl chloride).

The type of plastic extruder machine used in the manufacturing process depends on the type of plastic material being processed and the desired end-product. For example, a single screw barrel extruder is typically used for processing materials such as PE, PS, PC, ABS, PET, and PP, while a conical twin screw barrel extruder or parallel twin screw barrel extruder is used for processing PVC.

There are many manufacturers of plastic extruder machines that produce single screw barrel extruders, conical twin screw barrel extruders, and parallel twin screw barrel extruders. Some popular manufacturers include KraussMaffei, Battenfeld-Cincinnati, Milacron, Toshiba Machine, and Coperion.

2 . Brief Application

The High Precision Machining Customized Single Extruder Screw Barrels Plastic Machine Screw and Barrel for PP/PE is a type of extruder screw and barrel that is specifically designed for processing polypropylene (PP) and polyethylene (PE) plastics. It is used in plastic extrusion machines to melt and process these materials into various forms such as sheets, pipes, films, and other plastic products.

This screw and barrel set is customized to meet the specific requirements of the plastic extrusion process and is manufactured with high precision machining techniques to ensure accuracy and quality. The screw and barrel are typically made from high-grade alloy steel and undergo special surface treatments such as nitriding or bimetallic coatings to increase their wear resistance and durability.

The High Precision Machining Customized Single Extruder Screw Barrels Plastic Machine Screw and Barrel for PP/PE is designed to provide high efficiency and productivity in plastic extrusion applications. It has a high surface area-to-volume ratio, which allows for efficient heat transfer and melting of the plastic material. It also has a tight screw pitch and a high screw speed, which generates high shear forces that are necessary for melting and processing PP and PE plastics.

Overall, the High Precision Machining Customized Single Extruder Screw Barrels Plastic Machine Screw and Barrel for PP/PE is a high-quality and reliable component for plastic extrusion machines that ensures consistent and efficient processing of PP and PE plastics.

3 . Features:

The Conical Twin Screw Barrel is a type of extruder screw and barrel that has several unique features that make it ideal for processing PVC and other thermoplastic materials. Some of these features include:

1. Conical design: The Conical Twin Screw Barrel has a tapered or conical design, which allows for better material mixing and melting. The geometry of the barrel provides a longer processing length, which results in improved melting and dispersion of the plastic material.

2. High shear forces: The Conical Twin Screw Barrel is designed to generate high shear forces, which are required to melt and process PVC. The high shear forces are achieved through the use of a tight screw pitch and a high screw speed.

3. Self-cleaning: The Conical Twin Screw Barrel has a self-cleaning design that helps to prevent material buildup and reduces the need for frequent cleaning. The tapered design of the barrel allows for more efficient material flow and reduces the risk of material stagnation.

4. Wear-resistant: The Conical Twin Screw Barrel is constructed of high-quality materials that are wear-resistant and durable. The use of high-grade alloy steel and special surface treatments such as nitriding or bimetallic coatings ensures that the barrel has a long service life.

5. Versatility: The Conical Twin Screw Barrel can be used in a wide range of plastic extrusion applications, including profile extrusion, pipe and tubing extrusion, sheet extrusion, and cable and wire coating. Its versatility makes it a popular choice for plastic extrusion manufacturers.

Overall, the Conical Twin Screw Barrel's unique design and features make it an efficient and cost-effective option for processing PVC and other thermoplastic materials.

4 . Screw&barrel use material

| Raw material |

The finished product processing requirements |

| 38CrMoAIA, SACM645 |

Nitriding treatment |

| Cr12MoV, Cr12, |

Alloy steel |

38CrMoAIA, SACM645, 40Cr, AISI4140,

42CrMo |

Alloy steel |

| 4Cr5MoSiV1,SKD-61,SKD-11 |

Bimetallic of the inner hole centrifugal casting |

| GHII3 |

nature hard after high temperature |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!