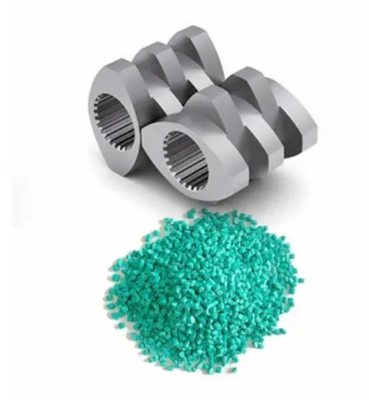

W6mo5cr4V2 Screw Element and Barrel Wear Resistance Screw Segment for Parallel Twin Extruder Mixing Cylinder Element

1 . Factory introduction

We are a professional manufacturer of nickel base alloy, Hastelloy alloy, tungsten carbide alloy, cobalt base alloy and H.I.P liner sleeve.

Screw elements are the main working parts for twin screw extruder which determined the quality and output of plastic products.With high quality,the screw elements assure plastic molecular mixing,cutting,spreading as well as reacting among themselves etc.Extremely high self cleaning performance assure the high quality of the whole production line,for this,our company combiend our experience for years,the merits about foreign countries and the customer's use,then take them into action,designed all kinds of suitable processing screw element with reasonable parameters,high self cleaning performance,wear resistance,corrosion-resistance.

Good quality high wear resistance screw elements spare parts for twin screw extruder are components that are made of high-quality materials and designed to withstand the extreme conditions and stresses of the extrusion process. These parts are critical to the performance and longevity of your twin screw extruder.

Some examples of good quality, high wear resistance screw element spare parts include:

-

Screw elements - made from materials such as high-speed steel or tungsten carbide, these can be coated with wear-resistant materials to further enhance their durability.

-

Barrel liners - typically made from nitrided steel, ceramic, or bimetallic materials, these liners protect the barrel from wear caused by abrasive materials or high temperatures.

-

Feeding screws - designed to handle materials that are difficult to feed into the extruder, these screws have specialized designs that help prevent clogging or bridging.

-

Mixing elements - used to ensure thorough mixing of materials in the extruder, these elements are often made from specialized materials such as hardened tool steel or carbide.

In summary, good quality high wear resistance screw elements spare parts help improve the efficiency and reliability of your twin screw extruder, ensuring that it operates at peak performance for longer periods of time.

2 . W6Mo5Cr4V2 High Speed Steel

W6Mo5Cr4V2 is a high-speed steel, the corresponding grade is M2 steel. It is composed of elements such as carbon, molybdenum, chromium, tungsten and silicon, and has excellent properties such as high hardness, high toughness and wear resistance, so it is widely used in the manufacture of various high-speed cutting tools and molds.

Features of 6542 high speed steel: It is a representative steel grade of tungsten-molybdenum series general-purpose high-speed steel. It has high toughness, good thermoplasticity, wear resistance better than W18Cr4V, high hardness, red hardness and high temperature hardness. It can be used to manufacture various cutting tools with high impact force, large-scale general cutting tools and thermoplastic forming cutting tools, as well as worn parts under high load, cold working molds, etc. 6542 heat treatment: quenching, preheating at 730-840°C, heating at 1210-1230°C (salt bath furnace) or 1210-1230°C (box furnace), oil cooling, tempering twice at 540-560°C, each time 2hW6Mo5Cr4V2 : 62-65 degrees (HRC), if it is a salt bath furnace >=64HRC, annealing <=255HB.

The material composition of W6Mo5Cr4V2. Among them, the content of carbon element is between 0.80% and 1.10%, which can improve the hardness and wear resistance of steel; the content of molybdenum element is between 4.50% and 5.50%, which can increase the strength and wear resistance of steel; chromium element The content of tungsten is between 3.80% and 4.40%, which can improve the hardness and corrosion resistance of steel; the content of tungsten element is between 5.50% and 6.75%, which can improve the hardness and wear resistance of steel; the content of silicon element is 0.20% Between % and 0.40%, the strength and corrosion resistance of steel can be improved.

The hardness of W6Mo5Cr4V2 steel is as high as 63-65 HRC, which belongs to the category of high-hardness steel. At the same time, its toughness is also very good, and it has good wear resistance and cutting performance. These properties make W6Mo5Cr4V2 steel widely used in the manufacture of high-strength and high wear-resistant tools and molds such as high-speed drills, milling cutters, gear cutters, cutting tools, and stamping dies.

W6Mo5Cr4V2 is a high-speed steel with excellent properties and is widely used in the manufacture of high-speed cutting tools and molds, as well as high-strength and high-wear-resistant parts in other fields.

specification:

Screw diameter: Φ26mm to Φ135 mm

L/D ratio: 36 to 68.

Material:Alloy-Steel of High Quality

1)38 CrMoAlA

2)CW6Mo5Cr4V2

We have screw elements "made in China in ranging from 26mm to 135 mm in more than 30 different metallurgies. we supply elements which exceed your expectations in terms of precision, appearance, durability, process requirements and ultimately price-performance-ratio.

W6Mo5Cr4v2 Chemical Composition

| |

C |

SI |

Mn |

P |

S |

Cr |

Mo |

V |

W |

Cu |

Ni |

| W % |

0.88 |

0.35 |

0.3 |

0.023 |

0.003 |

4.03 |

4.81 |

1.86 |

5.95 |

0.12 |

0.24 |

We can satisfy your different material needs:

According to appearance design,

According to Material

-For wear application:

Tool Steel:W6Mo5Cr4V2

PM-HIP material:WR5,WR13,WR14,CPM10V,CPM9V.

-For corrosion application:

38CrMoAla

PM-HIP material:WR4,WR13,WR14,CPM10V,CPM9V.

-For wear and corrosion application:

PM-HIP material:WR13,WR14,CPM10V,CPM9V.

-Other materials:

Stainless Steel:316L,440C etc.

3 . The advantages

The W6Mo5Cr4V2 extruder screw element is made from a high-speed tool steel known as W6Mo5Cr4V2, also referred to as M2 steel. This material is widely used in the manufacturing of cutting tools and has specific properties that make it suitable for extrusion applications. Here are some key characteristics and advantages of the W6Mo5Cr4V2 extruder screw element:

High Wear Resistance: W6Mo5Cr4V2 is a high-speed tool steel known for its exceptional wear resistance. This property makes it well-suited for extrusion processes that involve abrasive materials or high-wear applications. The screw element can withstand the continuous friction and wear encountered during extrusion, resulting in extended service life and reduced downtime for replacements.

Excellent Heat Resistance: W6Mo5Cr4V2 exhibits excellent heat resistance, allowing it to maintain its hardness and mechanical properties even at high processing temperatures. This is important in extrusion processes that involve elevated temperatures, ensuring the screw element retains its performance and shape under demanding conditions.

Good Toughness: Despite its high hardness, W6Mo5Cr4V2 also possesses good toughness, which helps prevent brittle fracture and damage during operation. The combination of wear resistance and toughness allows the screw element to withstand the mechanical stresses and impacts experienced in extrusion processes.

Precise Machinability: W6Mo5Cr4V2 is known for its excellent machinability, making it easier to manufacture complex screw element designs with high precision. This allows for the creation of intricate screw profiles that optimize material mixing, melting, and conveying in the extrusion process, resulting in improved product quality and consistency.

Versatility: The W6Mo5Cr4V2 extruder screw element is suitable for a wide range of extrusion applications, including plastics, rubber, and other materials. Its versatility makes it a popular choice for various industries that rely on extrusion processes.

Key Features:

1) Tool steel, the steel has a high hardenability and thermal cracking resistance, the steel contains a higher content of tungsten,molybdenum,chromium and alum, good wear resistance, toughness is relatively weakened, with good heat resistance.

2) High hardness,Hardenallity HRC up to 65.

Co-rotating Twin Screw Elements for:

-W&P:ZSK-MC

-Theysohn:TSK

-SM:TEK-HS

-Labtech:LTE

-Berstorff:ZE

-Maris:TM-W

-Feddem:FED-MTS

-Leistritz:ZSE/LSB

-APV:MP65

-JSW-TEX

-TOSHLBA:TEM

-KEYA,RuiYA,LANTAI,Umm-N

4 . Applicatons

Plastics Extrusion: The W6Mo5Cr4V2 screw element is commonly used in plastics extrusion processes, including the production of plastic pipes, profiles, films, and sheets. Plastics often contain additives, fillers, or reinforcing agents that can be abrasive, and the W6Mo5Cr4V2 material's high wear resistance makes it suitable for such applications.

Rubber Extrusion: Rubber extrusion involves processing elastomeric materials to create profiles, seals, gaskets, and other rubber products. The W6Mo5Cr4V2 screw element's wear resistance and toughness enable it to withstand the abrasive nature of rubber compounds, resulting in prolonged service life and consistent product quality.

Food Processing: In food processing applications, the W6Mo5Cr4V2 extruder screw element can be utilized where abrasive or high-wear materials are involved. For example, in the production of extruded snacks, pasta, or pet food, the screw element's wear resistance ensures longevity and maintains hygiene standards.

Recycled Materials: Extrusion processes that involve recycled materials often contain impurities such as contaminants, fillers, or residual metal particles that can accelerate wear on the screw element. The W6Mo5Cr4V2's high wear resistance makes it suitable for extruding recycled materials, allowing for efficient processing and maintaining product quality.

High-Temperature Extrusion: Certain extrusion processes, such as those involving high-temperature polymers or composites, require screw elements that can withstand the elevated temperatures. The W6Mo5Cr4V2 material's excellent heat resistance makes it suitable for these applications, ensuring the screw element remains robust and retains its mechanical properties even at high processing temperatures.

5 . Our QC Control

Spectroscopic Component

German Digimar Altimeter

Dye penetrant inspection(PT Test)

Ultrasonic Flaw Detection (UT Test)

6 . Our detection

Three Coordinate Measuring Machine

Rockwell Hardness Tester

Carbon Sulfur Detector

Abrasive Wear Testing Machine

7 . Our Advantage

1) Independent research and development of materials and processes can ensure the performance and process of materials to the maximum extent, and greatly prolong the service life compared with ordinary products.

2) Independently develop the process of key products, and constantly improve and enhance the old process to achieve the best product performance.

3) Continuously improving and optimizing product appearance of the composite layer ,which greatly improved the service life of products.

Welcome to inquiry:

BLOOM(suzhou) Materials Co.,Ltd

Contact Person: Ms. Miranda

Tel: 0086-15250395817

Email: sales1@ttxalloy.com

Fax: 86-512-89598069

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!