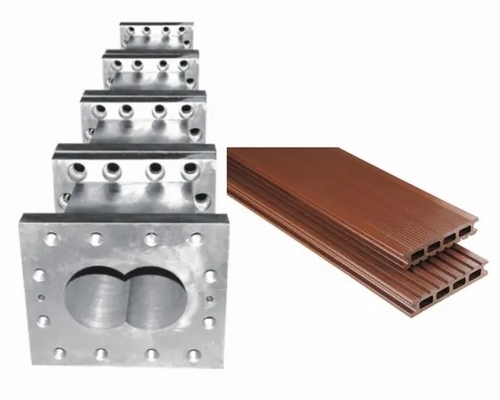

Parallel Twin Screw Extruder Pet Extruder Screw And Barrel Used In The Plastic Industry

Product Description:

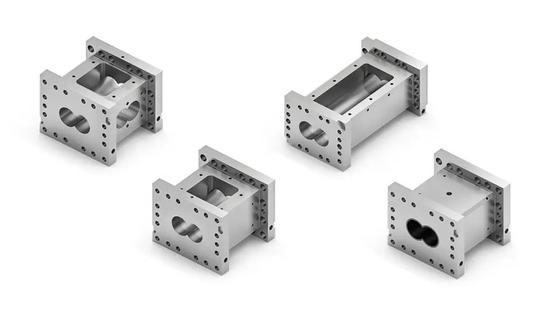

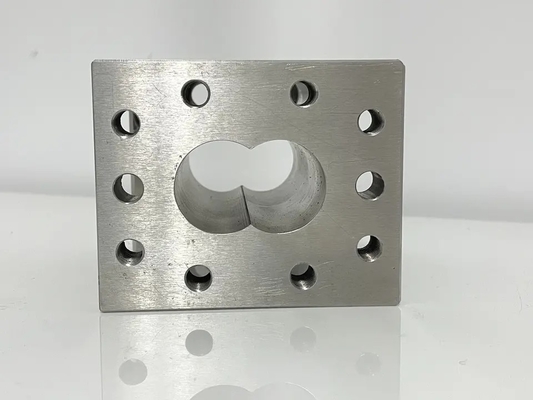

A parallel twin-screw extruder is a machine used in the plastics industry for processing polymers and creating plastic products. The machine consists of two parallel screws that rotate in opposite directions within a barrel. The screws intermesh with each other to move the plastic material through the extruder, where it is melted, mixed, and homogenized before being formed into the desired shape.

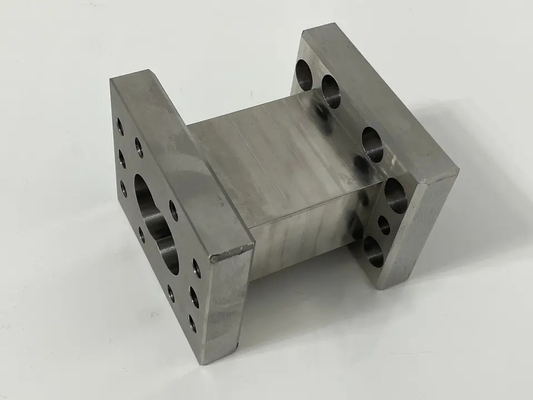

PET extruder screw and barrel specifically refer to the components within the twin-screw extruder that are used for processing PET (polyethylene terephthalate) plastic. The screw is a helical shaft that rotates within the barrel and conveys the material through the extruder, while the barrel is the cylindrical housing in which the screw rotates. The PET extruder screw and barrel are designed specifically for processing PET, which requires high processing temperatures and shear forces to achieve proper melting and mixing. These components are typically made of high-quality materials, such as nitride steel or bimetallic alloys, to ensure durability and longevity.

Bloom manufacture screw elements,barrels and other extruder machines.Screw elements are the main working parts for twin screw extruder which determined the quality and output of plastic products.With high quality,the screw elements assure plastic molecular mixing,cutting,spreading as well as reacting among themselves etc.Extremely high self cleaning performance assure the high quality of the whole production line,for this,our company combiend our experience for years,the merits about foreign countries and the customer’s use,then take them into action,designed all kinds of suitable processing screw element with reasonable parameters,high self cleaning performance,wear resistance,corrosion-resistance.

The function of screw element is mainly used to convey materials. Feeding and degassing sections generally have the long pitch to improve the material conveying and degassing. For material of low bulk density, feeding sections can use deep channel components to increase feeding capacity. The metering extruded segmented screw elements generally adopt the small pitch which is used to pressurize, improve the density of the material at the die head, and make the extrusion more stable.

Bloom manufacture screw element suitable for the following extruder products brand:

| No. |

Brand Name |

|

1

|

APV |

| 2 |

KOBE |

| 3 |

OMC |

| 4 |

Buhler |

| 5 |

Kraussmaffei |

| 6 |

Theysohn |

| 7 |

Buss |

| 8 |

Berstorff |

| 9 |

Toshiba |

| 10 |

Clextral |

| 11 |

Labtech |

| 12 |

USEON |

| 13 |

Coperion |

| 14 |

Lantai |

| 15 |

JSW |

| 16 |

Leistritz |

| 17 |

Keya |

| 18 |

Maris |

| 19 |

others |

We can satisfy your different material needs:

A . according to appearance design

Convey screw segment

Mixing screw segment

Kneading block&disk

Transition screw element

Deep groave transfer element

Screw element for side feeder

1/2/3 flighted screw element

OEM special screw element

B . according to materials

For wear application:

Tool steel:W6Mo5Cr4V2

PM-HIP material:WR5,WR13,WR14,CPM10V,CPM9V

For corrosion application:

38CrMoAla

PM-HIP material:WR4,WR13,WR14,CPM10V,CPM9V

For wear and corrosion application:

PM-HIP material:WR13,WR14,CPM10V,CPM9V

Other materials:

Stainless Steel:316L,440C etc.

1.Made of high speed steel (W6Mo5Cr4V2 and M2),Vacuum heating treatment and overall hardening, high wear-resistance and toughness.

2.Made nitrider steel (38CrMoAIA). high hardness, super toughness, anti-corrosion and anti-burst.

3.Made of HIP material imported from Europe (super wear-resistance powder metallurgical steel X245 and WR5).With features of high wear-resistance. high torque, anti-corrosion and anti-burst, this type of screw elements is used to produce such engineering plastics as that of more than 50% fiber glass.

4.Made of Hastelloy C-276 (00Cr16Mo16W4),super anti-corrosive nickel alloy. this type of screw elements is used to produce fluoroplastics(F46).

Screw and barrel accessories are important components for conical twin screw extrusion systems used in PVC and WPC profile applications. These accessories help to enhance the performance and efficiency of the extrusion process and ensure the quality of the finished products.

Here are some examples of screw and barrel accessories for conical twin screws used in PVC and WPC profile extrusion:

1. Mixing elements: These are special screw elements that are used to enhance the mixing and homogenization of the PVC or WPC materials. They can improve the consistency of the material and reduce the risk of defects in the finished products.

2. Side feeders: These are auxiliary devices that are attached to the extruder barrel to introduce additional materials, such as fillers or colorants, into the extrusion process. They can improve the properties and appearance of the finished products.

3. Temperature sensors: These are sensors that are installed in the barrel to monitor the temperature of the PVC or WPC materials during the extrusion process. They ensure that the temperature is consistent and within the optimal range for the materials, which can improve the quality of the finished products.

4. Pressure sensors: These are sensors that are installed in the barrel to monitor the pressure of the PVC or WPC materials during the extrusion process. They ensure that the pressure is consistent and within the optimal range for the materials, which can improve the quality of the finished products.

Overall, screw and barrel accessories play a crucial role in ensuring the performance, efficiency, and quality of the extrusion process for PVC and WPC profile applications.

Production Process Show

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!