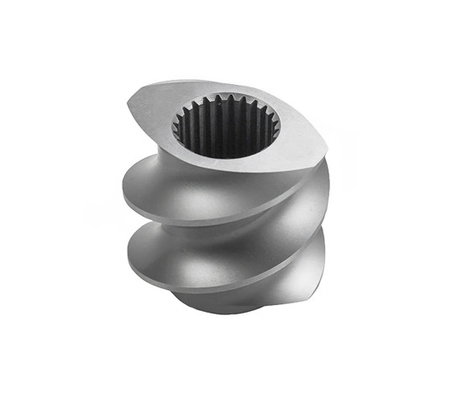

Twin Screw Extruder Screws and Barrels Converying Elements W6mo5cr4V2 / 38crmoala / Hip for Famous Brand Machine

1 . Factory introduction

We are a professional manufacturer of nickel base alloy, Hastelloy alloy, tungsten carbide alloy, cobalt base alloy and H.I.P liner sleeve.

We have provided super wear-resistant high corrosion resistance bushing for many domestic and foreign parallel twin-screw extruder customers and modification enterprises, and can be developed according to customer needs, combined with the actual conditions of high quality non-standard products, Oze product performance is excellent, stable quality, reasonable price, timely delivery, perfect after-sales.

Twin screw extruder screws and barrels conveying elements are essential components of a twin screw extruder that work together to achieve the desired processing result. These parts help to convey, melt, mix, and shape raw materials into a final product.

W6mo5cr4V2, 38crmoala, and Hip (Hot Isostatic Pressing) are types of high-quality materials that are commonly used to manufacture twin screw extruder screws and barrels conveying elements. These materials offer excellent wear resistance, high-temperature resistance, and good mechanical properties, making them ideal for use in the extrusion process.

Here are some key features of these materials:

-

W6mo5cr4V2: Also known as HSS-Co, this material is a type of high-speed steel that offers excellent wear resistance, toughness, and high-temperature strength. It is suitable for use in applications where high cutting speeds and temperatures are required.

-

38crmoala: This material is a type of nitrided steel that offers excellent wear resistance, corrosion resistance, and toughness. It is commonly used in the manufacture of screws and barrels for plastic extrusion processes.

-

Hip: Hot Isostatic Pressing (HIP) is a manufacturing process that involves applying high pressure and high temperature to a material to improve its mechanical properties. Materials manufactured using Hip have higher density, improved strength, and better wear resistance.

In summary, twin screw extruder screws and barrels conveying elements made from W6mo5cr4V2, 38crmoala, and Hip materials offer excellent wear resistance, high-temperature resistance, and good mechanical properties. These features ensure that the extrusion process operates at peak performance, delivering high-quality products with consistent output standards.

2 . The usage of Extruder Screws and Barrels Converying Elements

Twin screw extruder screws and barrels conveying elements are critical components of a twin screw extruder that work together to convey, melt, mix, and shape raw materials into a final product. These parts are essential for achieving the desired processing result and performance of the extruder.

Here are some key uses of twin screw extruder screws and barrels conveying elements:

-

Conveying: Feed screws and conveying elements are used to transport raw materials along the length of the extruder barrel towards the die or downstream equipment.

-

Melting: Melting is achieved by using kneading blocks, mixing elements, and distributive mixing elements. These elements facilitate the melting process by applying high shear forces, heat, and pressure to the material.

-

Mixing: Mixing elements are designed to create dispersive and distributive mixing of different materials and additives in the extruder. They can deliver a homogeneous and uniform mixture of materials, ensuring consistent quality and performance of the end product.

-

Shaping: Shaping elements, such as compression sleeves, restrictors, and dies, are used to control the flow and pressure of the melted material. The shaping elements ensure that the extruded product has the desired shape, size, and texture.

3 . The advantages

a . Improved efficiency: By choosing the right combination of screws and barrels conveying elements, manufacturers can optimize the extrusion process and minimize wastage of raw materials. This results in improved efficiency and reduced production costs.

b . Enhanced mixing capability: The use of specialized kneading blocks, mixing elements, and distributive mixing elements can improve the homogeneity and dispersion of additives and fillers in the extruded product. This leads to a more uniform product quality and better performance characteristics.

c . Extended lifespan: High-quality screws and barrels conveying elements made from durable materials can provide a longer lifespan for the extruder equipment. This reduces downtime due to wear and tear, maintenance needs, and repair costs.

d . Increased versatility: Twin screw extruders with interchangeable screws and barrels conveying elements can be used for a variety of processing applications with different products and materials. This flexibility allows manufacturers to produce a wide range of products with one piece of equipment.

e . Consistency and repeatability: Screws and barrels conveying elements play a critical role in determining the output quality of the extruder. By selecting the appropriate combination of these elements, manufacturers can achieve consistent and repeatable processing outcomes, leading to higher product quality standards.

4 . Applicatons

The twin-screw extruder is a versatile and efficient machine used in various industries for processing materials such as plastics, rubber, food, and pharmaceuticals. The screws and barrels are the most critical components of the twin-screw extruder, responsible for conveying, mixing, melting, and pumping the material through the machine.

Here are some of the applications of the twin screw extruder screws and barrels:

-

Mixing and compounding: The screws and barrels of the twin-screw extruder can be designed with different elements to achieve specific mixing and compounding functions. They can combine two or more materials, break down agglomerates, disperse fillers, and incorporate additives evenly into the polymer matrix.

-

Melting and devolatilization: The high shear and heat generated by the twin-screw extruder screws and barrels can melt thermoplastics, thermosets, and elastomers. At the same time, they can remove volatile components, moisture, and other contaminants from the material.

-

Reactive processing: The twin-screw extruder screws and barrels can facilitate chemical reactions between two or more materials. For instance, they can perform grafting, crosslinking, chain extension, and polymerization reactions by adding initiators, catalysts, and monomers.

-

Extrusion and shaping: The twin-screw extruder screws and barrels can shape the melted material into a variety of forms, such as sheets, tubes, profiles, fibers, and pellets. This process enables manufacturers to create custom-designed products with unique properties and specifications.

In summary, the twin-screw extruder screws and barrels play a crucial role in the production of various materials and products. They provide manufacturers with a versatile and efficient way to process, mix, compounding, melt, react, and shape materials according to their specific needs.

5 . Our QC Control

Spectroscopic Component

German Digimar Altimeter

Dye penetrant inspection(PT Test)

Ultrasonic Flaw Detection (UT Test)

6 . Our detection

Three Coordinate Measuring Machine

Rockwell Hardness Tester

Carbon Sulfur Detector

Abrasive Wear Testing Machine

7 . Our Advantage

1) Independent research and development of materials and processes can ensure the performance and process of materials to the maximum extent, and greatly prolong the service life compared with ordinary products.

2) Independently develop the process of key products, and constantly improve and enhance the old process to achieve the best product performance.

3) Continuously improving and optimizing product appearance of the composite layer ,which greatly improved the service life of products.

Welcome to inquiry:

BLOOM(suzhou) Materials Co.,Ltd

Contact Person: Ms. Miranda

Tel: 0086-15250395817

Email: sales1@ttxalloy.com

Fax: 86-512-89598069

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!