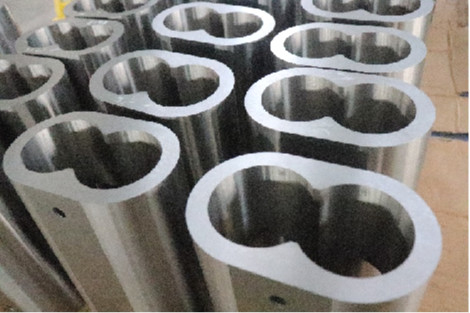

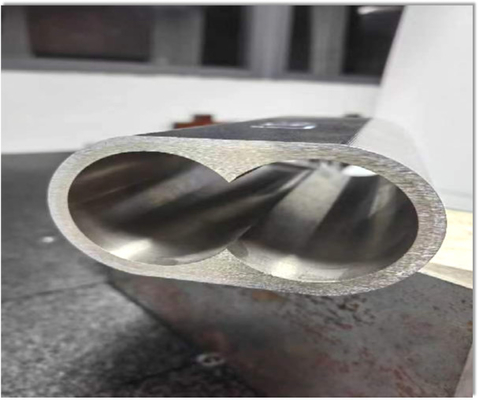

Twin Screw Extruder Bimetallic Sleeve Liner / Bimetallic Bushing

1 . Factory introduction

We are a professional manufacturer of nickel base alloy, Hastelloy alloy, tungsten carbide alloy, cobalt base alloy and H.I.P liner sleeve.

We have provided super wear-resistant high corrosion resistance bushing for many domestic and foreign parallel twin-screw extruder customers and modification enterprises, and can be developed according to customer needs, combined with the actual conditions of high quality non-standard products, Oze product performance is excellent, stable quality, reasonable price, timely delivery, perfect after-sales.

A Twin Screw Extruder Bimetallic Sleeve Liner is a wear-resistant component used in twin-screw extruders. It is designed to protect the extruder barrel from the abrasive and corrosive effects of the materials processed through the machine during operation.

The bimetallic sleeve liner is made up of two layers: an outer layer made of a high-strength alloy that provides wear resistance, and an inner layer made of a lower-cost material that provides structural support. The two layers are metallurgically bonded together to form a single, durable component.

The use of a twin screw extruder bimetallic sleeve liner helps to extend the life of the extruder barrel by providing superior wear resistance and reducing maintenance costs. This component is commonly used in the plastics, food, and chemical industries, where twin-screw extruders are used to process a wide range of materials into different forms such as pellets, flakes, or shapes.

2 . The usage of the Twin Screw Extruder Bimetallic Sleeve

a. Improved Wear Resistance: The bimetallic design provides superior wear resistance compared to traditional liners, resulting in longer service life and reduced downtime.

b . Corrosion Resistance: The inner layer of the liner is made of a highly corrosion-resistant material, which protects the extruder barrel from damage caused by corrosive materials or processing conditions.

c . Enhanced Performance: The liner's unique design helps to improve process efficiency, reduce energy consumption, and increase throughput.

d . Cost-effective: The use of bimetallic sleeves can be a cost-effective alternative to replacing the entire extruder barrel, especially when dealing with high-wear applications.

e . Easy Installation: The sleeve can be easily installed and removed, allowing for quick maintenance and replacement.

Overall, the Twin Screw Extruder Bimetallic Sleeve Liner offers a durable, efficient, and cost-effective solution for extrusion processing.

3 . The Twin Screw Extruder Bimetallic Sleeve Liner offers several advantages, including:

a . Improved Wear Resistance: The bimetallic design provides superior wear resistance compared to traditional liners, resulting in longer service life and reduced downtime.

b . Corrosion Resistance: The inner layer of the liner is made of a highly corrosion-resistant material, which protects the extruder barrel from damage caused by corrosive materials or processing conditions.

c . Enhanced Performance: The liner's unique design helps to improve process efficiency, reduce energy consumption, and increase throughput.

d . Cost-effective: The use of bimetallic sleeves can be a cost-effective alternative to replacing the entire extruder barrel, especially when dealing with high-wear applications.

e . Easy Installation: The sleeve can be easily installed and removed, allowing for quick maintenance and replacement.

4 . Applicatons

The Twin Screw Extruder Bimetallic Sleeve Liner is used as a replacement part in the extrusion process of various materials such as plastics, rubber, and food products. It serves as a protective and wear-resistant barrier between the extruder barrel and the screw, increasing the lifespan of both components and improving the efficiency of the extrusion process. The bimetallic construction of the sleeve liner provides enhanced durability and resistance to corrosion, allowing for longer periods of use before requiring replacement.

5 . Our QC Control

Spectroscopic Component

German Digimar Altimeter

Dye penetrant inspection(PT Test)

Ultrasonic Flaw Detection (UT Test)

6 . Our detection

Three Coordinate Measuring Machine

Rockwell Hardness Tester

Carbon Sulfur Detector

Abrasive Wear Testing Machine

7 . Our Advantage

1) Independent research and development of materials and processes can ensure the performance and process of materials to the maximum extent, and greatly prolong the service life compared with ordinary products.

2) Independently develop the process of key products, and constantly improve and enhance the old process to achieve the best product performance.

3) Continuously improving and optimizing product appearance of the composite layer ,which greatly improved the service life of products.

Welcome to inquiry:

BLOOM(suzhou) Materials Co.,Ltd

Contact Person: Ms. Miranda

Tel: 0086-15250395817

Email: sales1@ttxalloy.com

Fax: 86-512-89598069

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!