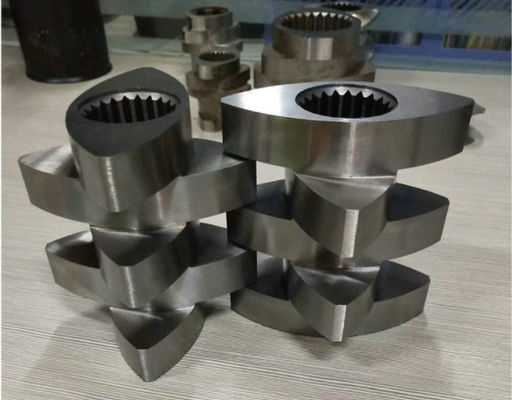

Modular Structure Screw And Barrel For Plastic Twin-Screw Extruder

Extruder Screw PVC Conical Twin Screw PP PS PC PE PET ABS PMMA GPPS Parallel Twin Screw Barrel Manufacturer

Product Description:

Bloom manufacture screw elements,barrels and other extruder machinesWe have provided machines with matching screw and barrel, such as engel (Engel), davis-standard (Davis standard), weber (Weber), berstorff (Berstorff), Battenfeld, Cincinnati, Taiwan Zhuyou, South Nanrong, Zhende, Haitian, Haitai, Hangzhou Tairui, Chenhsong, Korea Woojin, Japan Sumitomo, sumida, Liansu, Hongqi, Jugang, Yuanfeng, Xiongsu, etc. Domestic and foreign plastic machinery companies.

Twin-screw extruders can be further divided into: parallel twin-screw extruders and conical twin-screw extruders;At present,In Chiana single-screw extruder is the most widely used, suitable for extrusion processing of general materials. Because the twin-screw extruder has more heat generated by friction, the shearing of the material is relatively uniform, the conveying capacity of the screw is large, the extrusion is relatively stable, and the material stays in the barrel for a long time, so the material is mixed evenly.

Twin-screw extruder/granulator application

What is the application of twin-screw extruder? Twin-screw extruder is an important equipment in plastic processing machinery. It is not only suitable for extrusion molding and mixing processing of polymer materials, but its use has been expanded to food, feed, electrodes, explosives, building materials, Packaging, pulp, ceramics, chemicals, LED materials and other fields. The high-speed screw of the extruder also brings a series of difficulties to be overcome: the reduction of the residence time of the material in the screw will lead to uneven mixing and plasticization of the material, and the excessive shearing of the material may cause the material to rise sharply and thermally decompose. Difficulties in controlling the stability of the extrudate will cause fluctuations in the geometric dimensions of the extrudate. The accuracy of the related auxiliary devices and control systems must be improved. The increased wear of the screw and barrel requires the use of high wear-resistant and ultra-high wear-resistant materials. Problems such as how to improve its service life under running conditions all need to be solved. The electrical automation control of the extruder in the working process is also developing continuously. The traditional electrical control is realized by the stand-alone automatic instrument respectively. Now it has developed to the touch screen, PLC, Electrical control system composed of temperature control template, frequency conversion speed regulation, etc. Everyone knows that extruders are constantly developing and their uses will become more and more extensive.

The segmentation of the screw and its function

1) The screw is generally divided into 5 sections: conveying section, melting section, mixing section, exhaust section, and homogenizing section. the

1. Conveying section, conveying materials and preventing overflow. the

2. The melting section, which fully melts and homogenizes the material through heat transfer and frictional shearing. the

3. The mixing section further refines and evens the size of the material components to form an ideal structure, which has the function of distributive and dispersive mixing. the

4. The exhaust section discharges impurities such as water vapor and low molecular weight substances. the

5. In the homogenization (metering) section, conveying and pressurizing, a certain pressure is established to make the material at the die mouth have a certain density, and at the same time, it is further mixed, and finally achieves the purpose of smooth extrusion and granulation.

|

Model

|

Screw major diameter (D/mm)

|

Thread root diameter(d/mm)

|

D/d

|

Center distance(mm)

|

|

BLM-20

|

21.7

|

14

|

1.55

|

18

|

|

BLM-36

|

35.6

|

23.6

|

1.51

|

30

|

|

BLM-50

|

50.5

|

32.5

|

1.55

|

42

|

|

BLM-52

|

51.4

|

33.8

|

1.52

|

43

|

|

BLM-65

|

62.4

|

40.4

|

1.54

|

52

|

|

BLM-75

|

71

|

47

|

1.51

|

60

|

|

BLM-85

|

81

|

53.8

|

1.51

|

67.8

|

|

BLM-95

|

93

|

61

|

1.52

|

78

|

Production Process Show

Testing Equipments Show

Packing&Delivery

Company Introduction

Our company Bloom(Suzhou) Materials Co., Ltd is a trading and we focus on Replacement parts for Twin Screw Extruder. So far has over then 5 years of research and development production experience. Manufacturing Barrels, Gearboxes, Overall Liners and Screw Elements for Twin Screw Extruder. Our products cover all kinds of wear and corrosion resistant spare parts such as screw elements , barrels, shafts, plugs, couplings and so on. The screw diameter ranges from dia12.mm to dia.350mm. We do not produce single metal barrels and screw parts, but we also researched and produce bimetallic extruded screw barrels, which will make the life time of the parts double or triple increased. Our factory has strong technical force, excellent processing equipment, advanced production technology, strict inspection system and perfect after-sales service. My factory OUZI technology is the main supplier of spare parts of Leistritz China. We welcome all the friend oversea to contact and test my products, we are sure that Quality proves everything.If You give us one chance , we will return you inconceivable quality increased.

Conical Twin Screw Extruder

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!