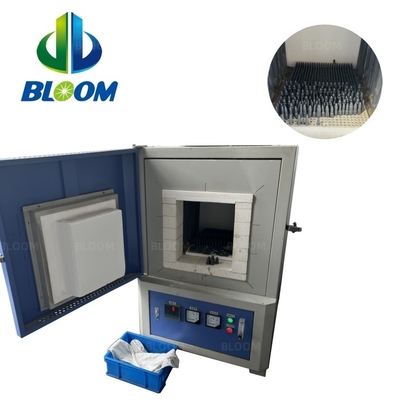

Manufacturer Direct High Quality Vacuum Atmosphere Muffle Furnace With High Temperature

Product Description

A muffle furnace is a kind of heat treatment equipment. Its main function is to perform operations

such as sintering, ashing, melting and heat treatment on the samples. It is widely applied in

laboratories, industrial production and scientific research.

The electric furnace adopts humanized design, beautiful and easy to operate, and the outer layer of paint is sprayed with high

temperature baking technology. High temperature resistance, oxidation resistance, acid and alkali resistance. Color selection is

aging resistant tone, will not cause the appearance color fade due to a long time of use.

Parameters

| Name |

Heating Treatment furnace |

| Material |

Alloy |

| Condition |

Brand new |

| Weight |

200kg |

| Voltage |

220/380V |

| Applicable Industries |

Spot Welding |

| Warranty of core components |

12 months after shipment |

| Original |

China |

| Package |

Wooden case |

| Package size |

90x60x70cm/120X120X110 cm

|

High temperature atmosphere furnace series is a horizontal vacuum chamber furnace atmosphere, can also be called anaerobic annealing furnace, atmosphere or vacuum sintering furnace, specifically designed for use on material under vacuum and the atmosphere environment (such as inert gas) sintering, high temperature can reach 1800 ℃ the introduction of foreign technology, independent research and development production, energy saving, and the new furnace. With reasonable double hull structure, the surface temperature is less than or equal to 40 ℃, beautiful appearance generous, is made of cold rolled steel plate, the numerical control machine tools and high precision laser cutting machine, CNC bending machine, surface with beautiful, luxurious, double color oxide powder electrostatic spraying, so as to achieve durable, no fading, high temperature resistant, corrosion resistant surface treatment.

Heating elements: choose different heating elements according to the furnace temperature, heating elements are divided into: electric furnace wire, resistance belt, silicon carbon rod, silicon molybdenum rod, molybdenum wire.

Inner bladder material: the inner bladder is made of imported warm refractory material, constructed by technology. Strong thermal shock resistance, good corrosion resistance, no collapse, no crystallization, no slag, long service life!

Temperature control mode: microcomputer intelligent regulation technology, PID regulation, automatic control, self-setting function; Multi-program programming, and can control various heating, heat preservation, cooling procedures; Power regulation; High temperature control accuracy; Integrated module thyristor control, phase shift trigger. Protection device: independent overtemperature protection, overpressure, overcurrent, leakage, short circuit protection, high degree of automation, all indicators reach the level.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!