Manual Tip Dresser Blade Holder Customized Design for Cutter Blade Resistance Welding Electrode Tip Dresser Accessory

1. Description:

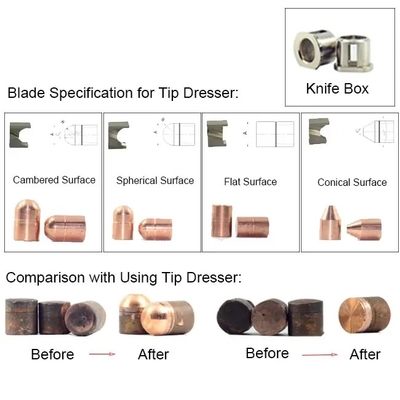

Electrode maintenance is critical to weld quality. Specify an electrode shape — and help it stay that way — to maintain the consistency of each weld. Even with proper weld parameters and water cooling, copper electrodes wear. Electrode Tip Dresser (ETD) can help you achieve better, more consistent welds, without a tiring and labor-intensive routine.

Proper tip dressing can solve a number of weld quality issues, including undersized or stuck welds, non-round welds, poor class-A appearance and excessive indentation (information via the WeldHelp Troubleshooting Guide).

Cutting and reshaping with the easy and fast pneumatic tip dresser is as simple as sharpening a pencil. Manual dresser shapes upper and lower caps simultaneously, saving time and ensuring electrode face alignment.

Unlike competitive units, the manual dresser features a large horizontal grip that easily fits hands wearing protective gloves while giving the operator stability, control and leverage while dressing.

Worn electrode tips produce either poor welds or no welds at all, limiting both quality and productivity. Two possible solutions to worn tips are to (1) replace them with new, or (2) recondition existing tips on either a lathe, drill press, or with a portable Electrode Dresser. Replacing tips is a costly and time consuming alternative. Reconditioning tips on standard machine shop equipment, although providing uniformly dressed electrodes, cuts valuable production time. Reconditioning worn tips with an Electrode Dresser, however, is a convenient, economical solution that minimizes downtime.

The function of the electrodes is to conduct the current and to withstand the high pressures in order to maintain a uniform contact area and to ensure the continued proper relationship between selected current and pressure. Uniform contacting areas should therefore be maintained.

Good weld quality is essential and depends, to a considerable degree, upon uniformity of the electrode contact surface. This surface tends to be deformed (mushroomed) with each weld. Primary causes for mushrooming are too soft electrode material, too high welding pressure, too small electrode contact surface, and most importantly, too high welding current. These conditions cause excessive heat build-up and softening of electrode tips. Welding of today´s coated materials also tends to contaminate the face of the electrodes.

Bloom's cutting baldes are made of high speed steel,which maintains a sharp edge for fast and reliable tip dressing.The cutters can be replaced easily when need to change the new ones

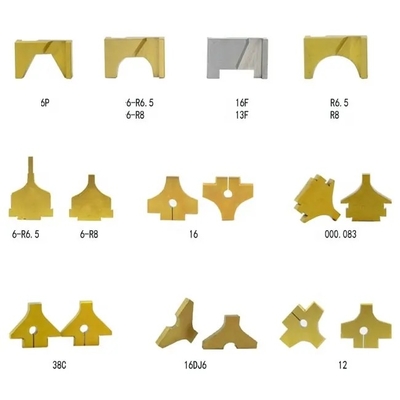

Bloom peovides cutters and holders for many popular makes and models of tip dressers,which helps reduce plant-wide equipment variation.

2. Spot Welder Tip Dresser Main Features

1) Small, lightweight and easy to operate.

2) Only need compressed air.

3) Low cost,high speed,reliable performance.

4) Standard size or customoized

5) Easy to change cutter and holder

We also make other type cutters and welcome your inquiry:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!