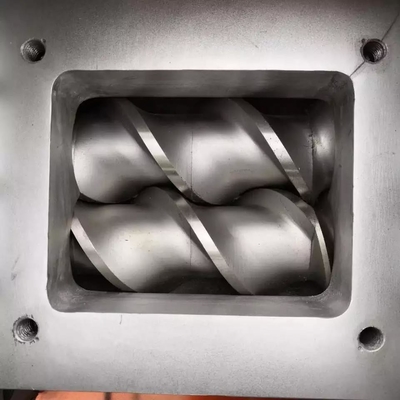

China Made Single Extruder Screw And Barrel For PVC Extrusion

1 . Description:

Conical twin screw and barrel cylinder has the advantage of lower rotation speed, smaller shear stress between the small screw

Good plasticization, high productivity, small shear force, stable pressure , less wear and tear and low cost.

Conical twin-screw and barrel is widely used in PVC products processing, especially for the production of PVC products with the output over 350Kg / h, because the parallel twin-screw and barrel costs less than conical twin-screw and barrel while it has more mature technology.

Conical twin-screw and barrel is successfully applied in PVC plate, pipe, profile, pellet and mould, at the same time, it solved the technical problem of low foaming, high foaming, high filling, wear and corrosion.

Usage:

It is the function of plastic for conveying, compaction, melting, mixing and pressure. All of these procedures are done through the rotation of the screw in the barrel.

Material:

Using 38 chromium molybdenum lithium material production, nitriding treatment, product quality assurance.

Maintenance of screw barrel:

1, the barrel does not reach the preset temperature, do not start the machine. The new electric heating generally requires the temperature to reach the set value of 30 minutes after the operation of the screw

2, each down more than half an hour or more, it is best to close the material inlet and clean the barrel, set insulation

3, to avoid the foreign body falling into the material barrel damaged screw and barrel. To prevent debris and metal debris falling into the hopper, if the processing of recycled materials, we need to add magnetic hopper to prevent iron filings into the barrel.

4, the use of anti saliva to determine the barrel of plastic melt completely, so as not to damage the transmission system parts screw back.

5, to avoid the phenomenon of idling and slipping of screw.

6, the use of new plastic, the material should be cleaned out of the material. The use of POM, PVC, PA+GF and other materials to minimize the degradation of raw materials, after the shutdown in a timely manner

Rinse.

7, avoid the POM and PVC at the same time mixed with the barrel, in the melt temperature will be a serious industrial accident caused by reaction.

| Product |

twin bimetallic conical screw and barrel |

| Material |

38 CrMoAlA(JIS SACM645); 42 CrMo(AISI 4140)

Cr12MoV(JIS SKD-11);4Cr5MoSiV1(JIS SKD-61) |

| Nitrided Hardness |

HV950°~1000° |

| Hardness after hardening and tempering |

HB260 ° |

| Nitrided Depth |

0.5~0.7mm |

| Nitrided Brittleness |

above 2 stage |

| Surface Roughness |

Ra0.4 |

| Screw straightness |

0.015mm |

| Hardess of surface chromium-plating after Nitriding |

HV≥950HV |

| Chromium plating Depth |

0.05~0.10mm |

| ALLoy Depth |

0.8~2.0mm |

| Alloy hardness |

HRC56°~65° |

| Alloy(bimetallic) |

iron,nickel,tungsten,molybdenum |

| Types of screw barrel |

Gradual type,mutant type,wave type,barrier type,double screen type,shunt type,separation type,exhaust type,pin type,mixed type,double-head type,three-head type,multi head type etc. |

2. Base Materials:

1). 38CrMoAlA(JIS SACM645) Nitriding.

2). 42CrMo(AISI 4140).

3). 4Cr5MoSi V1 (JIS SKD-61).

4). 9Cr18MOV

5). HPT

3 . Bimetallic alloy materials:

1). Fe-based alloy

2). Ni-based alloy/Deloro alloy

3). Co-based alloy

4). NiCo-based alloy

5). Tungsten carbide/Wolfram carbide

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!