Descriptions

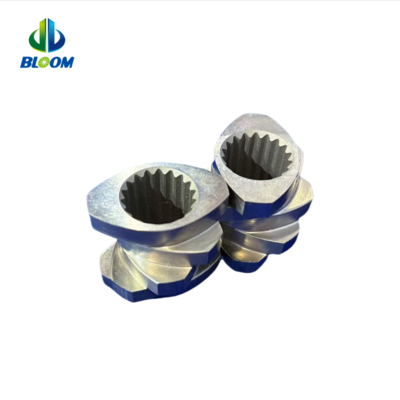

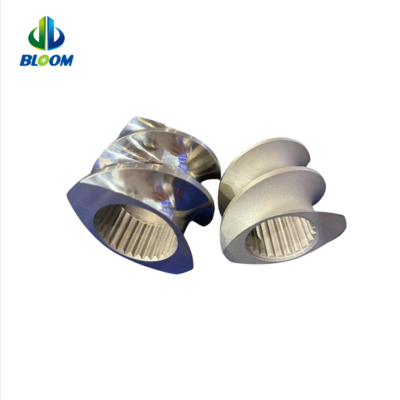

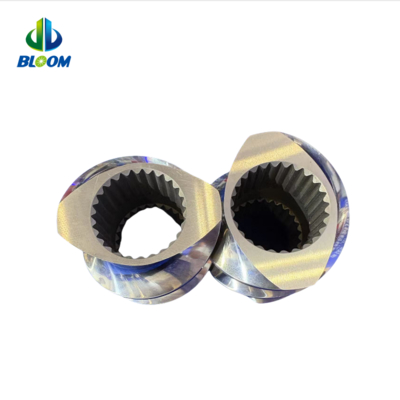

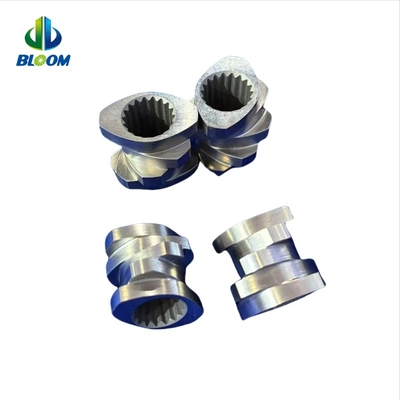

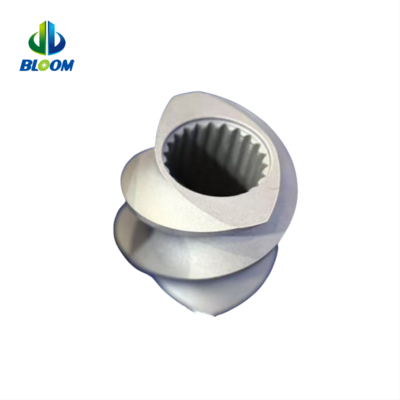

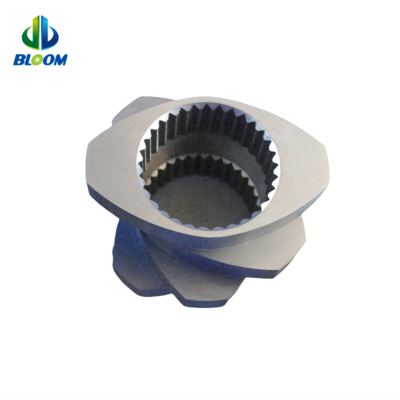

The screw inside the barrel is designed to interact with the material in a way that promotes

efficient mixing, melting, and forwarding. The design of the screw and its relationship with the

barrel can have a significant impact on the quality and output of the extruded product.

Detailed specifications

| Functions |

convey, mixing, kneading,transition of raw material to avoid piling up |

| Material |

38CrMoAl, D2, W6542, SS 440, Wr5 Wr14, Ni60 |

| Hardness |

HRC58-60 |

| Applicable machine |

Parallel twin screw Extruder machine |

Production process

Detailed photos

Reference cases

Company Profile

Bloom Suzhou Materials. We are mainly focused on ultra-wear and corrosion-resistant extruder

core components such as screw elements, barrels and bushings. We can offer new and refurbished

wear parts for all major makes of parallel twin-screw extruders. It is mainly covers plastics industry,

chemical industry, powder coating, food industry and so on.

We can fulfill their different requirements based on ample experience in alloy material and strong

support by independent design team.

Applications

What we can offer

1.How do I know if my screw or barrelneeds replacement?

signs of wearinclude decreased performance,increased energy consumption,and noticeable

damage to the screw flights or barrel surface.

2.What are the common causes of wear in extruder screws and barrel?

common causes of wearinclude abrasive materials,high temperatures,and prolonged usage

without proper maintenance.

3.How to optimize the performance of my injection screws?

optimizing performance involves regular monitoring ofwear,adjusting materials, and considering

upgrades or enhancements such as coatings or design modifications.

4.What measures can be taken to minimize wear in feed screws for plastic extrusion?

Minimizing wearinvolves selecting appropriate materials,improve design, maintaining proper

alignment,and implementing preventve maintenance schedules

5.How does wear in conical screws impact the efficiency of mixing and compounding processes?

Wearin conical screws can result in uneven mixing,reduced throughput,and increased energy

consumption,affectng the efciency ofmixing and compounding processes.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!